The resulting bend angle variation and sometimes the required adjustment to the flat layout contributes to the reason that machined parts typical tolerance of 0 002 in can routinely have tighter tolerances than precision sheet metal parts typical tolerance of 0 010 in.

Standard flatness tolerance for sheet metal.

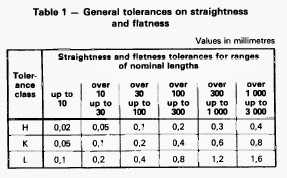

Relevant din standards for metal.

En 10 051 continuously hot rolled strip and plate sheet cut from wide strip of non alloy and alloy steels.

Linear tolerances should be held as loose as possible.

During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

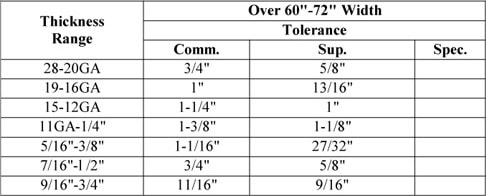

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances.

Plates can be out of flat for a number of reasons.

Ati sheet stainless steels are flat rolled products produced by continuous mill rolling available in coils or cut lengths.

And for machined components iso 2768 fh can be used.

For thicknesses lighter than 0 018 refer to.

Stainless steel sheet forms finishes and tolerances.

4 for widths over 6 ft these tolerances alloy for any 6 ft of total width.

For sheet metal parts iso 2768 mk is used.

Tolerance class is defined as per design requirements and manufacturing capability.

Tolerances of 010 should be considered minimum.

Sheet metal tolerances should not be tighter than necessary to make the part functional.

1989 general tolerances part 2.

Flatness tolerance thickness width maximum deviation in in from a horizontal inches inches flat surface in inches 0 062 60 0 40 60 0 50 0 062 60 0 40 60 0 50 stretcher leveled sheets specified to stretcher leveled standard of flatness exclusive of 1 4 2 3 4 and full hard tem pers of 200 and 300 series grades.

In general sheets 60 wide and under are to be no more than out of flat when laid on a flat surface.

General tolerance iso 2768 does not specify where to use these tolerances.

Sheet metal guage tolerances.

Standard tolerances sheet standard tolerances.

Tight tolerances raise the cost of manufacturing significantly.

In the above example m and k has defined the tolerance.

Thicknesses range from 0 018 to 0 1874 and widths range from 24 to 48.

Practical tolerances vary according to the design requirements.

Since rolled alloys also levels this product we work to the mill tolerances.

5 short span flatness is the deviation from flat over full span for spans 2 ft and less 2 tx51 is a general designation for the following stress relieved tempers.

And for machined components iso 27 68 fh can be used.

For sheet metal parts iso 27 68 mk is used.

Geometrical tolerances for features without individual tolerance indications.

T351 t451 t651 t851 t7351 and t7651.

En 10 259 wide strip and plate sheet made of stainless steel.

Relevant en standards for metal sheets and plates.